[car home Electric Vehicle Technology] won an order of 500,000 yuan before it went on the market, which is enough to show that Tesla MODEL 3 is hot, and even quite a few people are purely "blind" and have no idea what kind of car it is before booking. Recently, a blogger in a foreign forum leaked the maintenance manual of MODEL 3, so the body structure and materials of MODEL 3 were exposed, and what does this mean?

● MODEL 3 is not a simple miniature version of MODEL S?

Tesla showed a subversive change with traditional car companies. MODEL S and MODEL X designed by former Mazda designer Franz von Holzhausen have also been recognized by most people in design, but the taste of "traditional cars" on MODEL S and MODEL X seems to be slightly strong. In contrast, MODEL 3 is a product that is more in line with future trends.

MODEL 3′ s 100-kilometer acceleration is less than 6 seconds, and the 21700 lithium battery with higher energy density is used. The cruising range of the two versions is 354km and 499km respectively, and it can be seen from the 8 cameras and 12 radars arranged on the body that it has the basic hardware of Tesla Autopilot 2.0. It is only a set of software programs to realize the high-level autopilot function. Therefore, it is still very powerful from the configuration point of view.

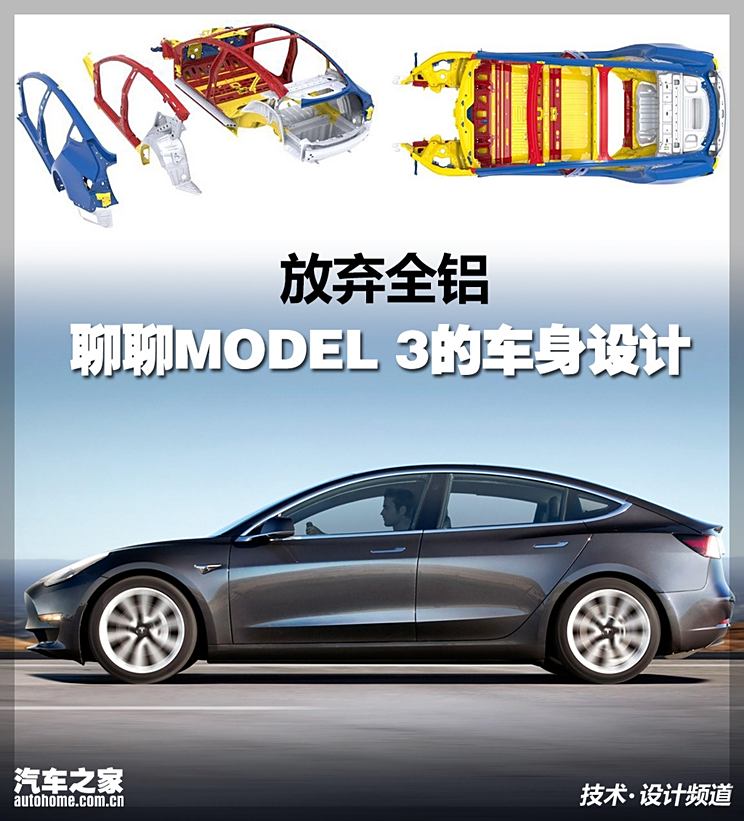

● Why didn’t MODEL 3 adopt an all-aluminum body?

Body material seems to be a means for emerging car companies to distinguish themselves from traditional car companies in the concept of building cars. All-aluminum body is considered by many people as the lightweight trend of future cars. However, why did the latecomer MODEL 3 change the material use scheme of MODEL S and MODEL X and adopt the steel-aluminum mixed body structure?

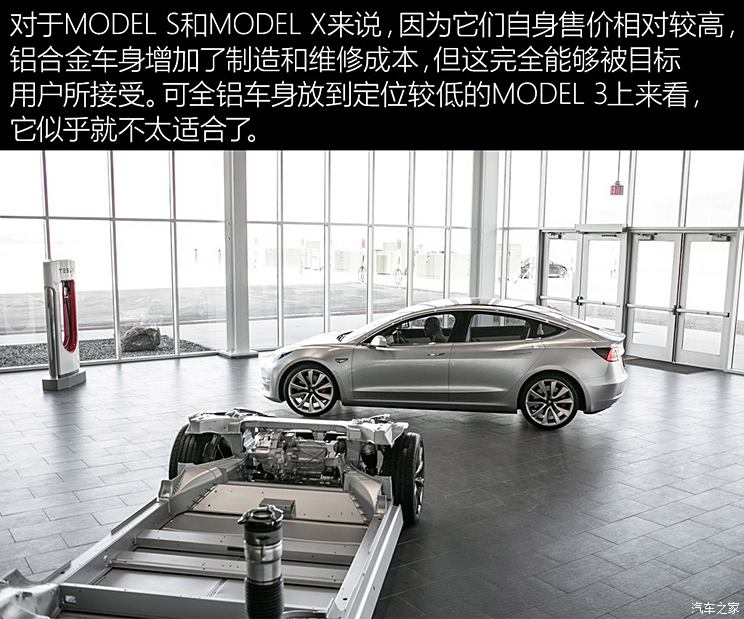

Aluminum alloy is light. Compared with the traditional steel body, MODEL S and MODEL X have greatly reduced the weight, so the power and economy will be improved accordingly. Of course, you don’t have to worry that the all-aluminum body is not strong. The technology of high-strength aluminum alloy has long been very mature. Through structural design, its strength can fully meet the requirements of automobiles. However, high-strength aluminum alloy is expensive, which is more expensive in manufacturing and maintenance than traditional steel. Therefore, at present, the all-aluminum body appears more on the relatively high-priced vehicles such as Land Rover Range Rover, jaguar XF and F-PACE.

Aluminum alloy is not only expensive in material procurement, but also more complicated in automobile manufacturing. Due to the material characteristics of aluminum alloy itself, in order to ensure sufficient strength, it needs a variety of riveting and welding processes in body-in-white assembly, and the natural processing cost will also increase.

Manufacturing cost is the main reason why Tesla decided to switch to steel-aluminum hybrid body, so it can further explore the price of products to attract more consumers.. Of course, this can also eliminate some consumers’ small concerns-the late maintenance cost of all-aluminum body is relatively high. When the car body is damaged by collision, it is difficult to reshape the aluminum alloy material. If the operation is improper, the parts are likely to crack or even break. After the damaged aluminum alloy parts, if the sheet metal process cannot be adjusted well, they can only be replaced as a whole. In addition, aluminum alloy materials need special technology to weld. Therefore, the all-aluminum body means that the later maintenance cost may be higher.

● What kind of body does MODEL 3 use?

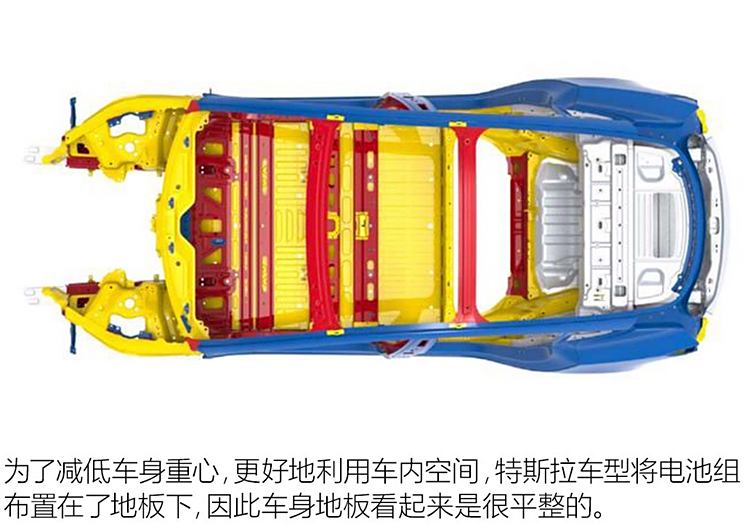

Lightweight and low cost, so how does Tesla do it? Yes, steel and aluminum alloy are mixed and used. The following is the latest exposed Tesla body structure.

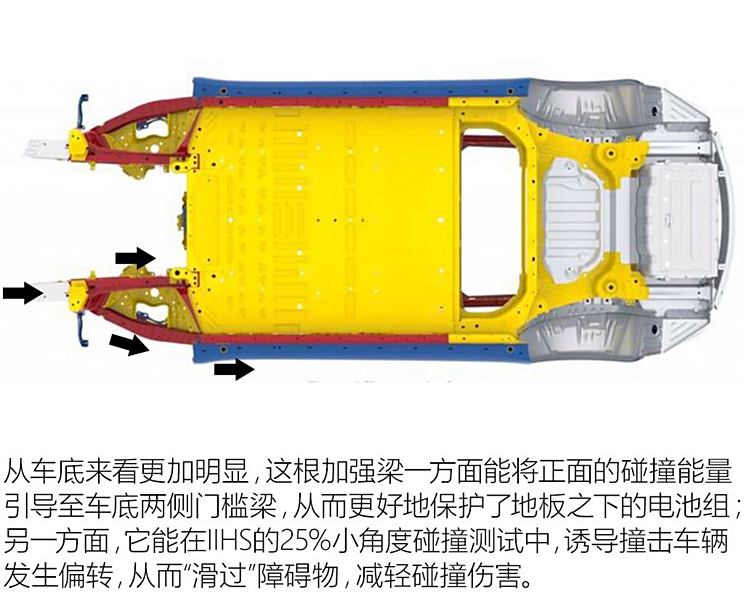

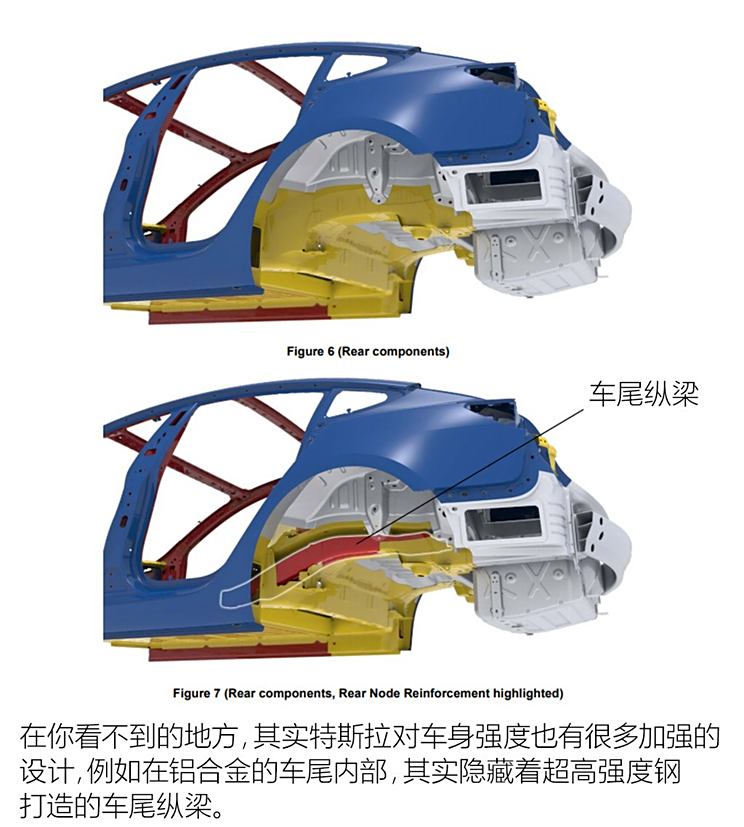

MODEL 3 uses ultra-high strength steel in the body side rail, A-pillar, B-pillar, roof side rail and floor beam, obviously to ensure the strength of the body main frame and improve the passive safety of the vehicle. For example, when dealing with frontal and side collisions, MODEL 3 can resist the impact energy and ensure the living space of the passenger compartment.

It is precisely because of the 25% small-angle collision test that the big brother Tesla MODEL S has not been able to get the "excellent+"evaluation on IIHS. Can MODEL 3 achieve better results through such strengthening measures? We can look forward to it.

The aluminum alloy material is concentrated in the tail, which may be related to the weight distribution before and after MODEL 3. We know that MODEL 3 adopts the form of pure motor rear wheel drive, and the rear bearing is subjected to more weight load of the whole vehicle, so in order to balance the weight distribution before and after, it is more appropriate to use lighter aluminum alloy at the tail.

Although MODEL 3 uses a large area of steel, due to the size, the vehicle weight is much lighter than MODEL S, and the vehicle weight is controlled at about 1.6-1.7 tons. The combination of aluminum alloy and steel combines various factors such as cost, power, economy and safety.

-Tesla’s internal side pillar impact test video is as follows:

More exciting videos are all on the car home video platform.

Perhaps the steel-aluminum hybrid body is also a trend in the future. Judging from the latest Mercedes-Benz S-Class and Audi A8, their bodies are made up of a variety of materials, the most representative of which is Audi A8, whose steel content has changed from 8% of the previous generation to 40%. Due to the progress of steel materials, the yield strength of ultra-high strength steel can reach more than 1500MPa, which is more conducive to improving the passive safety of vehicles. In addition, if the vehicle main frame wants to achieve a certain structural strength, the weight of this ultra-high strength steel may not be heavier than that of aluminum alloy.

● What does Tesla rely on to build MODEL 3?

At present, the main factory producing Tesla MODEL 3 white body is Fremont factory in the United States, which was once a factory jointly built by GM and Toyota. In 2010, Tesla CEO Musk bought the base for only half the estimated price at that time (about $42 million). Therefore, it can be said that Fremont factory still has some production experience in building steel body in white.

After MODEL S and MODEL X established brand image and recognition for Tesla, Musk began to take the more civilian product MODEL 3. In the face of greater shipments in the future, Tesla’s new Gigafactory factory will also play a role in providing lithium-ion batteries.

Summary:

Perhaps for consumers, how much aluminum alloy and steel are used is not so important. We only care about whether it is safe enough, whether the acceleration is not strong enough, whether the later maintenance is cheap, and so on. Judging from the price and positioning of MODEL 3, it is believed that the use of steel-aluminum hybrid body can also be accepted by consumers, because the later maintenance cost will be more affordable. What’s more, with the progress of ultra-high strength steel materials, perhaps the steel-aluminum hybrid body is also a development trend in the future. (Text car home Xia Zhimeng Image from the Internet)

关于作者