Huawei Cloud’s global headquarters has landed in Guizhou and Gui ‘an, Guiyang, becoming one of the regions with the largest number of super-large data centers in the world. The growth rate of digital economy has ranked first in the country for six consecutive years, and it has been approved to build 48 national-level pilot demonstrations; The State Council issued the "Opinions on Supporting Guizhou to Break a New Path in the Great Development of the Western Region in the New Era" (hereinafter referred to as "Document No.2 of New China Development"), and one of the strategic orientations given to Guizhou is "Digital Economy Development and Innovation Zone"; The National Development and Reform Commission, the Central Network Information Office, the Ministry of Industry and Information Technology, and the National Energy Administration jointly issued a document, agreeing to start the construction of eight national computing hub nodes in Guizhou and other places, and the "East Counting and West Computing" project was fully launched … … Big data has become a "beautiful business card" in Guizhou.

Under the "blessing" of the country’s double favorable policies, Guizhou, as the country’s first national-level comprehensive experimental zone for big data, is actively seizing historical opportunities, taking advantage of the situation, making every effort to seize new opportunities in implementing the digital economy strategy, and striving to make the digital economy an important engine to lead and promote the high-quality economic and social development of the province.

Since the establishment of China International Big Data Industry Expo (hereinafter referred to as "Digital Expo") in 2015, Guizhou has used data resources to turn into its own development advantages, and continued to make this world’s first national-level Expo with the theme of big data strong and focus on the frontier trends of the industry. Digital Expo has become an international grand event leading the development of the industry and a world-class platform for exchanging development ideas and creating cooperation opportunities.

In today’s Guizhou, many digital platforms are on the rise, digital enterprises are growing, and digital formats are emerging. The strong pulse of digital economy development can be felt everywhere. On May 26th, 2022 "Digital Expo" was held in Guiyang through online form, which made colorful Guizhou once again attract attention due to big data.

Seize the opportunity and turn the policy dividend into a driving force for development

On March 20th, the centralized groundbreaking ceremony for the first batch of projects of Guiyang Big Data Science and Technology Innovation City in 2022 was held in Gui ‘an New District. This time, eight projects were started, involving office buildings, commercial complexes, hotels, houses, affordable rental housing, schools and related facilities, with a total investment of about 6.5 billion yuan. The start of the first batch of projects marks that Gui ‘an New District has sounded the clarion call in an all-round way, and has taken a solid step towards high-level planning, high-standard promotion and high-quality construction of Guiyang Big Data Science and Technology Innovation City.

In February, 2021, General Secretary of the Supreme Leader visited Guizhou for investigation and gave Guizhou an important mission of "seizing new opportunities in implementing the digital economy strategy". In order to strive to be the "vanguard" of new machines in the implementation of digital economy strategy, Gui ‘an of Guiyang adheres to the development direction of high-end, green and intensive, plans to build Guiyang Big Data Science and Technology Innovation City, and strives to build Guizhou digital industry and talent gathering area, digital scene application demonstration area and ecological civilization exhibition area.

On December 22, 2021, the People’s Government of Guizhou Province approved the construction of Guiyang Big Data Science and Technology Innovation City in Gui ‘an New District. In January, 2022, the document No.2 of New China Development clearly supported Guizhou to promote the construction of the National Big Data Comprehensive Experimental Zone and Guiyang Big Data Science and Technology Innovation City, and to cultivate and expand emerging digital industries such as artificial intelligence, big data, blockchain and cloud computing.

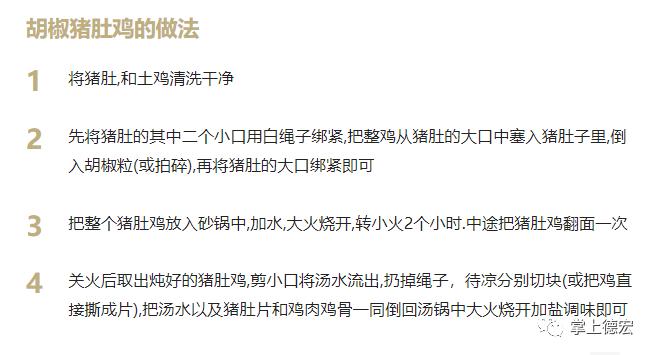

Guizhou Yudie Electric Co., Ltd. integrated production from intelligent manufacturing to intelligent warehousing, reducing costs and improving production quality and efficiency. Photo by Chen Hui

"The introduction of Document No.2 of New China Development has made Guiyang Gui ‘an more motivated and confident in building and using Science and Technology City." Gu Fugang, deputy director of Guiyang Big Data Development Administration, said that in 2022, Gui ‘an, Guiyang will make every effort to build Guiyang Big Data Science and Technology Innovation City, not only to formulate supporting policies and measures, but also to improve the production and living functions of Science and Technology Innovation City, and at the same time increase investment attraction, strive to build 1.2 million square meters of industrial and residential buildings, introduce 400 big data enterprises, and realize operating income of 3 billion yuan.

The pointer of time is dialed back to 2014, and China’s big data industry is still in its infancy. Guizhou, with the task of "carrying out big data resource circulation experiment", took the lead in establishing Guiyang Big Data Exchange. As the world’s first big data exchange, Guiyang Big Data Trading Platform provides comprehensive supporting services such as data confirmation and data pricing to the world through independent development of electronic trading system, maximizing data value and realizing data realization.

In the following years, Guizhou firmly seized the opportunity of big data development, took the construction of a national big data comprehensive experimental zone as the starting point, unswervingly promoted the strategic action of big data, and took the lead in taking the lead in the "breakthrough war" of big data. In 2020, the scale of digital economy in China will reach 39.2 trillion yuan, and Guizhou will occupy the first place in the country for six consecutive years with a growth rate of over 15%.

The big data industry has grown from scratch, and the development of the digital economy has flourished. Guizhou regards big data as the strategic engine of straightening corners and catching up later, and makes an article "Seize the opportunity of the times and catch up later" flourish, realizing a wonderful leap from "depression" of economic development to "highland" of digital industry development.

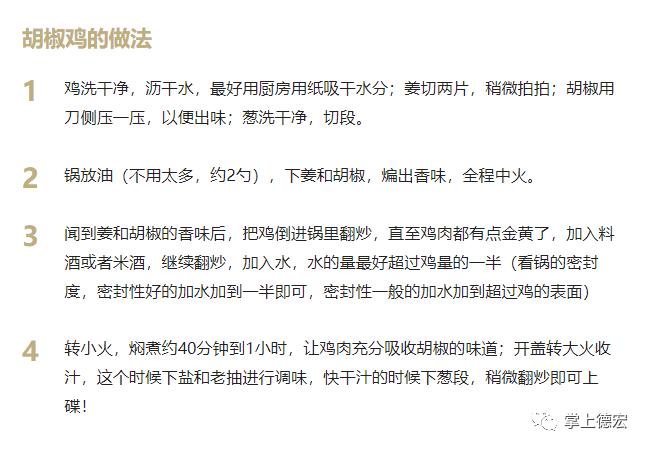

Deep integration of big data and agricultural economy in Guiao Agricultural Tourism Industry Demonstration Park. The picture shows workers pollinating fruit tomatoes in the eco-efficient fruit and vegetable picking experience hall. Photo by Chen Hui

In 2022, Guizhou’s big data industry once again ushered in a historic development opportunity. The No.2 document of New China Development and the policy of "East Counting and West Counting" project were both exerted and the dividends were superimposed, which injected strong development momentum into Guizhou, which struggled to seize new opportunities in implementing the digital economy strategy. To this end, the Development Plan of Strategic Emerging Industrial Clusters in Guizhou Province in the 14th Five-Year Plan clearly states that by 2025, the total output value of strategic emerging industrial clusters in the province will exceed 1.3 trillion yuan, and the added value will account for 15% of the regional GDP.

Plan the data center in advance and seize the commanding heights of computing power

"In the past, it may take more than 100 hours to render a film on a single frame. It can be completed within 1 to 5 minutes through the calculation of Gui’ an Supercomputing Center, and the efficiency is improved by thousands of times." Dai Kaiguo, a network engineer of Shenzhen Ruiyun Technology Co., Ltd., told reporters that the development of big data in Guizhou is booming, and high-performance computing resources make it inevitable for enterprises and institutions involved in big data to choose Guizhou.

It is precisely because of the super computing power of Gui ‘an Supercomputing Center that in January 2021, Shenzhen Ruiyun Technology Co., Ltd. took the lead in cooperating with the center to provide computing power for the post-production rendering of its film and television culture. In September of the same year, Guangzhou Yongsheng Animation Co., Ltd., which had long-term cooperation with Shenzhen Ruiyun Technology Co., Ltd., was "attracted" to Guizhou. Driven by singing animation, some industry benchmark enterprises such as Chengdu Dance Light and Shadow Animation Technology Co., Ltd. have settled in Guizhou.

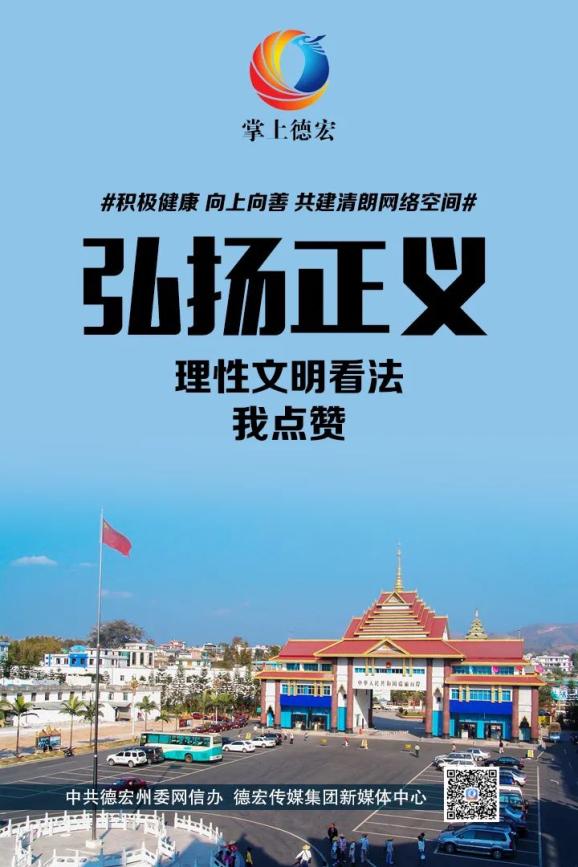

Aerial photography of Gui ‘an Huawei Cloud Data Center and Tencent Data Center. Photo by Feng Li

In the era of digital economy, computing power is the core productivity and the new focus of global strategic competition. In order to further promote the project of "calculating from the east to the west", the primary task of Guizhou is to improve the supply level of computing power, so that computing power can support the brand, receive business and make a good reputation. The data center is the "base" of computing power. For Guizhou, which unswervingly promotes the deepening of the big data strategy, it has already been at the forefront of the country in terms of data center construction.

Thanks to the unique advantages of low annual average temperature, stable geological structure and abundant water and coal resources, Guizhou has become an ideal place for data center construction. In May 2016, Guizhou was approved to build "China Southern Data Center Demonstration Base". Taking this opportunity, Guizhou stepped up planning and implementation of a number of leading, driving and landmark major projects.

In just a few years, Huawei, Tencent and Apple data centers have been built, and the number of key data centers that have been put into operation and under construction in the province has reached 25, including 11 very large data centers. It has formed a data center layout of "three places and two centers" with Gui ‘an in Guiyang as the core and Southwest Guizhou as the supplement. Gui ‘an in Guiyang has become one of the regions with the largest number of super-large data centers in the world.

Not only that, Guizhou has also built and opened 53,000 5G base stations, more than 1.5 million kilometers of communication optical cables, and the bandwidth of the Internet out of the province reached 28,000 g, 10 times that of 2015; Build a dedicated channel for Guiyang Gui ‘an Internet data and open a direct high-speed link to the Internet; Guiyang Gui ‘an national Internet backbone direct connection point was built, and 17 cities were directly connected, becoming the core hub of the national optical network information superhighway.

Technicians from China Unicom’s an yun data center patrol the micro-module inlet and outlet pipe valve pressure gauges in the computer room. The picture shows the largest cloud data center built by China Unicom in the south. Photo by Chen Hui

After years of development, Guizhou has become one of the regions with the largest concentration of super-large data centers in the world, and has the first-Mover advantage in the field of computing power. Standing at the new starting point of "calculating from the east to the west", Guizhou put forward a series of policies to support the construction of data center clusters, do a good job in industrial layout, develop upstream and downstream industries and seize the commanding heights of computing power with the goal of providing high-quality data computing services and taking the opportunity of building a "meta-universe".

"Guizhou will take the government’s guiding investment as the traction, give full play to the leverage and leading role of financial funds, set up various investment funds to support the construction of data center clusters, and support the major projects of big data centers by means of awards, interest subsidies and equity investment." The relevant person in charge of the Big Data Development Administration of Guizhou Province said that in the future, Guizhou will actively build upstream and downstream industrial clusters of data centers, and strive to reach 1 million standard racks and 4 million servers in the province’s data centers by the end of the 14 th Five-Year Plan.

"Number" makes full use of the strong rise of the 100 billion digital industry

On May 6th, the "Top 20 Edge Computing Enterprises in China in 2022" sponsored by the Edge Computing Community was announced, and Guizhou Bai Shanyun Technology Co., Ltd. was re-selected for its overall edge cloud service capability. As a local big data enterprise in Guizhou, Bai Shanyun Science and Technology Co., Ltd. has made great achievements in the "fertile soil" of digital economy development in Guizhou.

In the chip inductor workshop of Guiyang Shunluo Schindler Electronics Co., Ltd., the "head" of the winding machine is green, pulling the copper wire to wind the wire on the inductor skeleton the size of a rice grain. "The workshop has nearly 100 sets of high-frequency chip wound inductors such as AI intelligent sightseeing machines, which were officially put into production in January last year." Deng Shichun, assistant general manager of Guiyang Shunluo Xunda Electronics Co., Ltd., introduced that the workshop produces 800 million inductors every year, with an output value of about 500 million yuan.

Both Bai Shanyun and Shunluo Schindler are the epitome of the rapid development of electronic information manufacturing in Guizhou. Seize the opportunity of digital blue ocean, and the development of big data information industry in Guizhou has been flourishing. Entering a new journey of high-quality development, how to continue the leading edge of the digital economy in the country? Starting from digging deep into the value of data, Guizhou constantly stimulates the potential of digital economy and promotes the upgrading of data products.

The development of big data industry in Guizhou focuses on stimulating the potential of digital economy and making data products truly convenient and beneficial to the people. The picture shows the Agricultural Bank of China Guiyang Branch and medical institutions to build a smart "robot" on the line. Photo courtesy of Agricultural Bank of China Guiyang Branch

To this end, Guizhou highlights the "application belt industry", concentrates on building a 100 billion-level industrial chain big data electronic information industry cluster with international competitiveness, focusing on cultivating upstream and downstream industrial clusters of data centers, intelligent terminal industrial clusters and data fusion industrial clusters, and accelerating the construction of a national big data electronic information industry cluster.

Pay attention to investment promotion and business operation. Guizhou has made great efforts to promote the "streamline administration, delegate power, strengthen regulation and improve services" reform, attracting investment with the best service, making every effort to build a brand of "noble service" and building a domestic first-class business environment, so that investors can have a green light and a prosperous career in Guizhou.

The leading edge of big data development and good business environment in Guizhou have attracted many well-known international and domestic big data companies, such as Apple, Microsoft, Huawei and Tencent. A number of high-growth local enterprises, such as Manbang, Bai Shanyun and Zhongsheng Tyco, have flourished. Manbang and Longma Information have entered the top 100 Internet companies in China, and Bai Shanyun has been selected as "China Potential Unicorn Enterprise" & HELIP; … In 2021, the revenue of software and information technology services in Guizhou increased by 59.3% year-on-year, which was 41.6 percentage points higher than the national average, ranking first in the country in terms of growth rate.

Guizhou has the advantages of big data development and a good business environment, attracting a large number of enterprises to settle in. The picture shows the logistics digital port in Guiyang. Photo courtesy of Manbang Group.

At present, there are 52 enterprises with revenue of 100 million in software and information technology service industry in Guizhou. In order to promote the development of big data electronic information industry, Guizhou has made a layout from the top design, and issued the "Development Plan of Big Data Electronic Information Industry in Guizhou Province during the 14th Five-Year Plan" on April 8, 2022. It is clear that by 2025, the province’s big data electronic information industry will achieve an annual output value of 350 billion yuan, become a national gathering area of big data electronic information industry, and build a core hub for the circulation of national data production factors.

The main person in charge of the Guizhou Provincial Party Committee said that it will vigorously promote digital industry innovation, digital integration innovation, digital infrastructure innovation, digital governance innovation, and digital ecological innovation, keeping in mind the entrustment and seizing opportunities, carefully planning and fully promoting the construction of digital economy development innovation zones, and accelerating the high-quality development of the digital economy.