The domestic shield machine is new again!

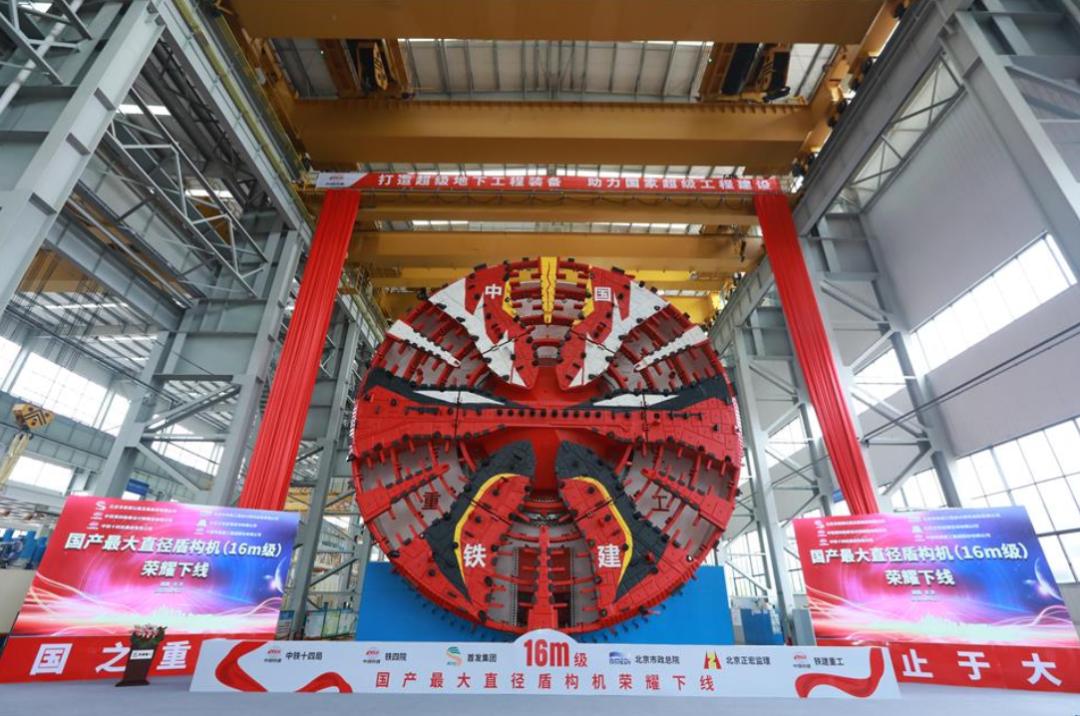

On September 27th, the "Jinghua" extra-large diameter shield machine rolled off the assembly line in Changsha. This shield machine is 150 meters long, with a total weight of 4,300 tons and a maximum excavation diameter of 16.07 meters. This is the largest diameter shield machine developed in China so far, and it will participate in the reconstruction project of Beijing East Sixth Ring Road after leaving the factory.

The equipment was jointly developed by China Railway Construction Heavy Industry Group and China Railway 14th Bureau Group, and it was the first time that Chinese enterprises successfully realized the industrial manufacture of 16m-class super-large diameter shield machine. The reporter saw at the scene that the equipment was huge, like a steel giant lying workshop, with a height of more than 5 floors. The cutter head painting extracted visual elements from Peking Opera masks, and took the red masks representing loyalty, courage and righteousness in Peking Opera as the design prototype. The appearance was bright and eye-catching, highlighting the regional cultural characteristics of Beijing.

Many netizens saw it and called this Facebook "absolutely"!

In fact, the painting of Beijing Opera theme of "Jinghua" is not the first case.

China shield machine has excellent performance, and its "skin" is also very distinctive.

China exports Russian money ("Victory"):

China exports to India:

China exports French edition:

China exports to Sri Lanka:

In terms of color, there are blue ones:

Red:

Green:

Colored:

Behind every "new skin" is the story of China people’s struggle to break the blockade and monopoly.

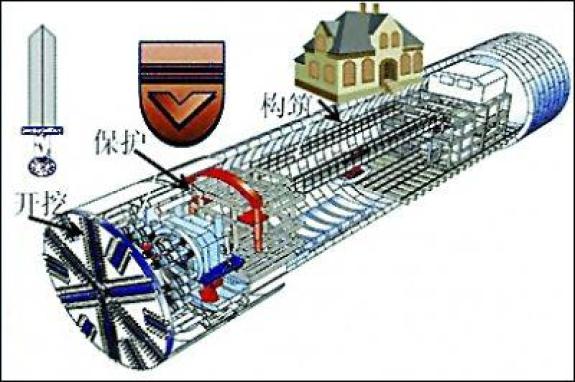

Shield machine, also known as tunnel boring machine, was invented and used in foreign countries as early as 1825.

Due to the difficulty in manufacturing, the shield machine market has been occupied by Germany, the United States and Japan for a long time.

Developed countries monopolize technology and market, and buyers have no bargaining power.

"Spending money depends on your face", and China at that time was no exception.

In 1997, when China was building the Qinling Tunnel of Xikang Railway, the first tunneling equipment was introduced from Wilt Company of Germany.

When I bought two machines, that was 700 million.

It was 700 million yuan in the 1990s, and people’s attitude was like that: Love buy buy, don’t buy it.

Tan Shunhui of China Railway Engineering Equipment Group recalled this past event and said that at that time, the right to speak about the price was in the hands of foreigners. He said that the money was as much as he wanted. If you want to make any changes, you should add the price first.

Because foreign countries have occupied the highest point in technology, their arrogance of looking down at people is the most unacceptable and uncomfortable.

The "after-sales service" of foreign experts is also very expensive, with an hourly salary of 600 to 800 euros.

Besides, when to repair it depends on people’s work schedule and mood.

In this way, foreign experts have to set up a cordon to prevent China people from watching.

In 2001, the foreign side proposed that an old shield machine should be sold at the price of a new shield, and the accessories should be increased by 100%.

In their view, China people can’t make it themselves, and they will accept the harsh conditions.

Generations of China people are fighting in their hearts: "We must use our own equipment in the future."

No matter how hard and bitter it is, we must build our machine!

Starting from the design drawings, China began to explore his own shield machine under the background of inexperience.

Really, start from scratch.

Follow suit, the shape is there, but it is still far from "domestic".

Li Jianbin of China Railway Industry said: "If you really do it yourself, you will know how difficult it is to manufacture the key components."

For example, knives, how many knives are arranged? What is the height? What is the spacing between knives? What is the opening rate of the cutter head?

China people don’t know these things, so they have to start from scratch and conduct theoretical research.

In actual work, the machine may encounter granite and limestone; May face hard soil, soft soil, silt, silty clay … These all need different tools according to different geology to make the best design.

It took China nearly five years to figure out the problem of cutting tools.

Under such difficulty, China people just chewed this bone down.

In 2008, China’s first shield machine with independent intellectual property rights was successfully rolled off the assembly line.

In 2013, the "Big Brother" German Wilt Company was acquired by China Railway Equipment.

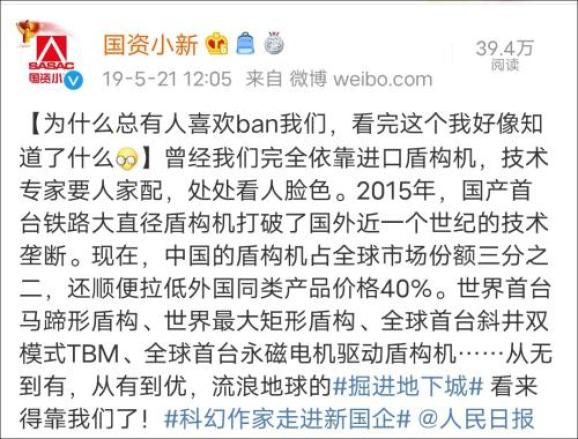

Nowadays, the domestic shield machine has broken the monopoly of foreign technology and market, and lowered the price of similar products by 40%.

Domestic shield machines have also reached the top in many fields, with innovations: the world’s first horseshoe shield, the world’s largest rectangular shield, the world’s first inclined shaft dual-mode TBM, and the world’s first permanent magnet motor-driven shield machine …

Being "stuck in the neck" Sorry, now it’s: "No one has me, and everyone has me."

Not only the technology is good, but also many styles, large output and low price.

"There is a Shenzhou in the sky, a dragon in the sea, and a shield in the ground", and "a great country’s weapon" is both a starting point and a monument.

Like for Hunan manufacturing!

(Source: Economic Daily Editor: Yan Xin Trainee Editor: Jiang Xiaojing)

Recommended reading

Xie Weijiang was appointed Vice Governor of Hunan Provincial People’s Government.

Hunan Free Trade Zone is coming, how can Changsha exert its strength?

Gather the voices of the world and tell the story of Changsha

Original title: "Made in Changsha! "Infrastructure Mad Devil" adds another weapon! 》

Read the original text

关于作者